ArmaFix AF

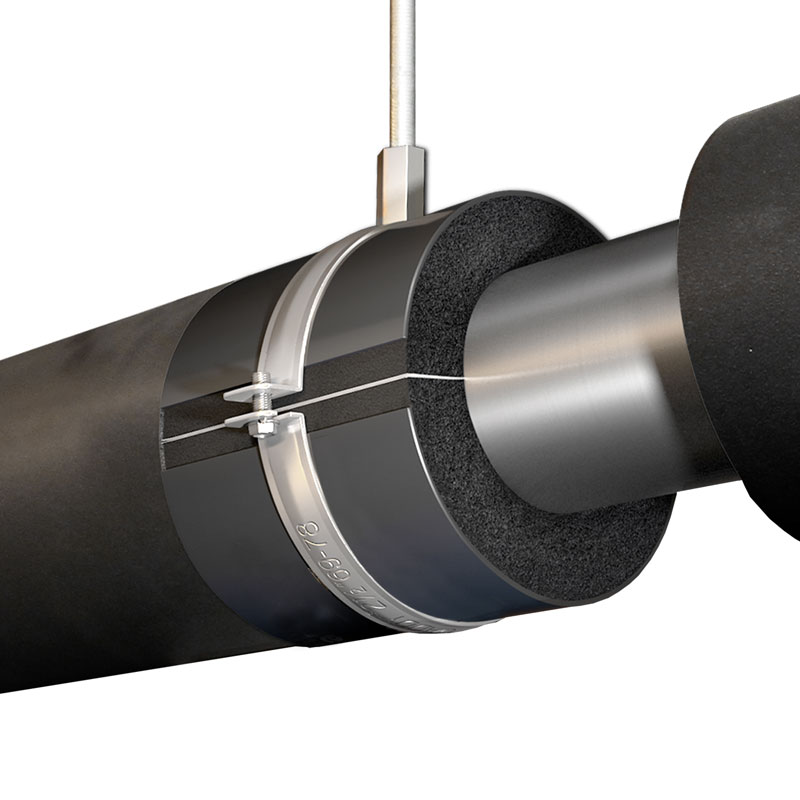

The cutting-edge pipe support

Technical information ArmaFix AF

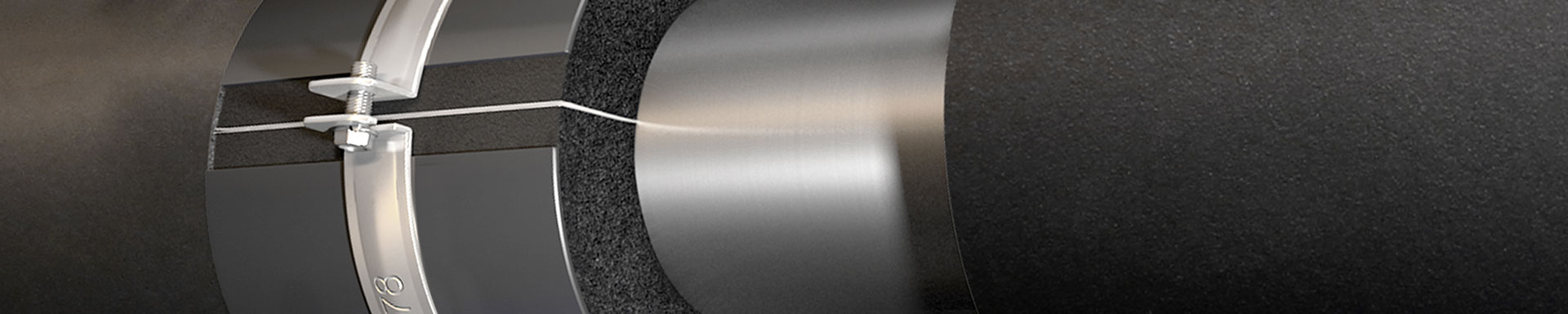

Material type

PET- foam bearing segments, embedded in and glued to AF/ArmaFlex elastomeric foam material. Outside bearing shells made of painted aluminium sheeting 0.8 mm thick, which simultaneously serves as a vapour barrier for the PET bearing segments.

Special features

- Traces of silicone can be found on the protection paper / foil used to protect self-adhesive closures.

| Property | Value / Assessment | Standard / Test method | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature range | ||||||||

| Service temperature |

| EN 14706, EN 14707, EN 14304 | ||||||

| Thermal conductivity | ||||||||

| Remarks | Same as AF/ArmaFlex.

Same as AF/ArmaFlex Evo. | EN ISO 13787, EN 12667, EN ISO 8497 | ||||||

| Fire Performance and Approvals | ||||||||

| Reaction to fire | Euroclass: E (L)

Entire System with AF/ArmaFlex: B / B(L)-s3, d0 Entire System with AF/ArmaFlex Evo: B / B(L)-s2, d0 | EN 13501-1, EN 13823, EN ISO 11925-2 | ||||||

| Surface flammability2 | low-flammable - 2010 FTP-Code (MED 96/98/EC, Module D) | IMO 2010 FTP Code, Part 5 | ||||||

| Fire performance | ||||||||

| Practical fire behaviour | Self extinguishing, does not drip, does not spread flames. | |||||||

| Resistance to water vapour | ||||||||

| Water vapour diffusion resistance factor | Same as AF/ArmaFlex

Same as AF/ArmaFlex Evo | EN 12086, EN 13469 | ||||||

| Physical attributes | ||||||||

| Density | 95 - 105 kg/m³ (pipe bearing segments) | |||||||

| Acoustic performance | ||||||||

| Reduction of structure-borne sound transmission | in combination with AF/ArmaFlex ≤ 28 dB(A) | EN ISO 3822-1 | ||||||

| Health and environment | ||||||||

| Additional features | MCCP-free | |||||||

| Other technical features | ||||||||

| Shelf life | 3 years | |||||||

| Storage | Can be stored in dry, clean rooms at normal relative humidity (50% to 70%) and ambient temperature (0 °C – 35 °C). | |||||||

1For temperatures below -50 °C please contact our Customer Service Center to request for the corresponding technical information. 2According to IMO 2010 FTP Code annex 2, clause 2.2 a fire technical test for smoke density and toxicity is not necessary. | ||||||||