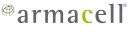

Technical insulation of process pipework & equipment

Planning for optimal process stability

High-performing process pipework & equipment

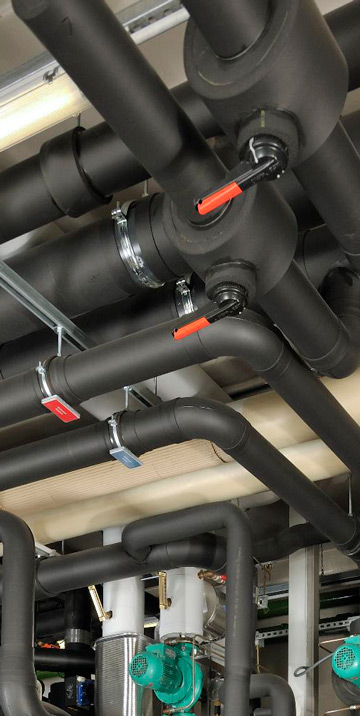

Process pipework and equipment depend on reliable thermal and acoustic insulation to transport steam, hot water, hot gasses or cold liquids and gases at controlled temperature and pressure levels. That requires a detailed understanding of operating and environmental conditions such as operating temperature, ambient temperature and humidity, wind speed and occasionally even solar radiation. The correct system design with elastomeric or aerogel-based thermal and acoustic insulation materials can significantly contribute to the process stability, overall performance, work safety and long-term reliability of process industry pipework and equipment, leading to more cost-, time- and energy-efficient operations.

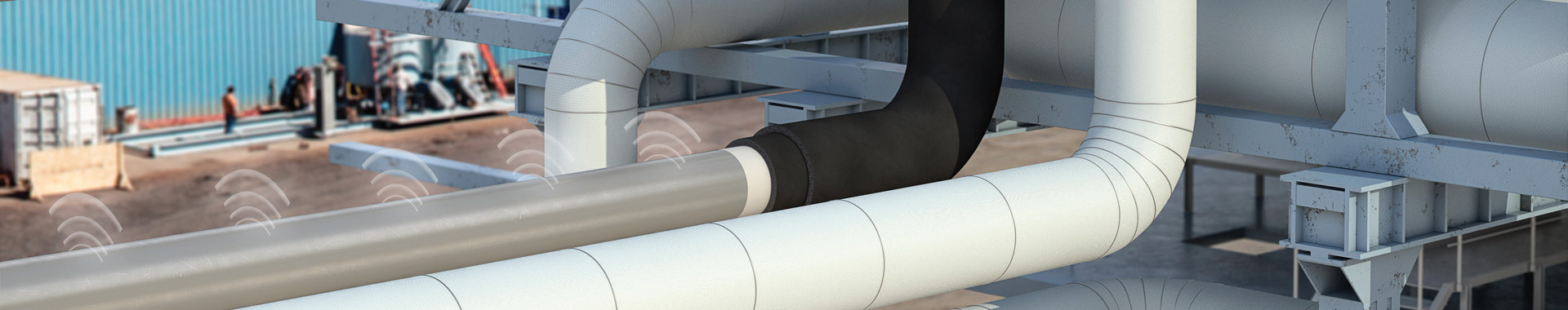

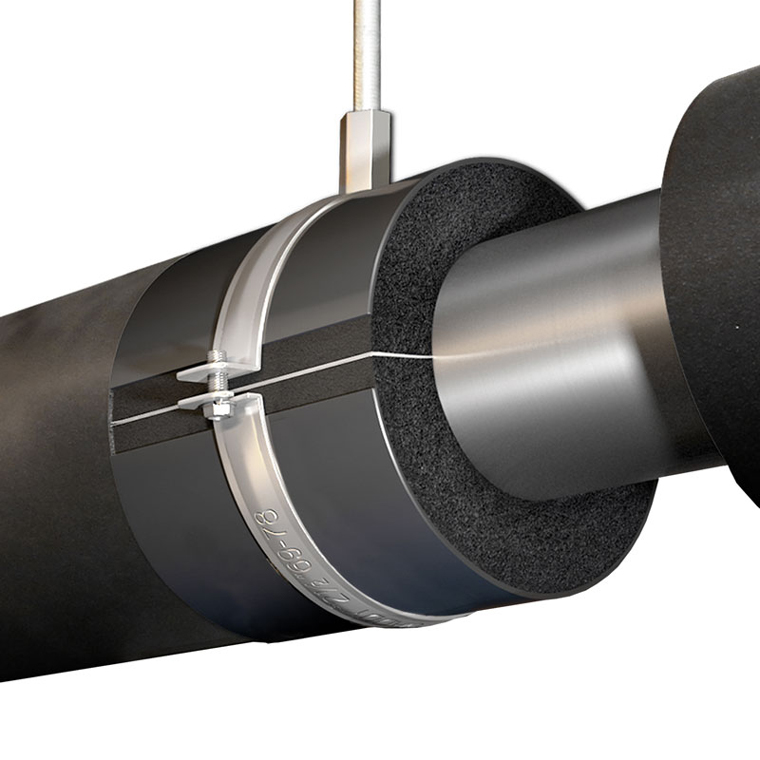

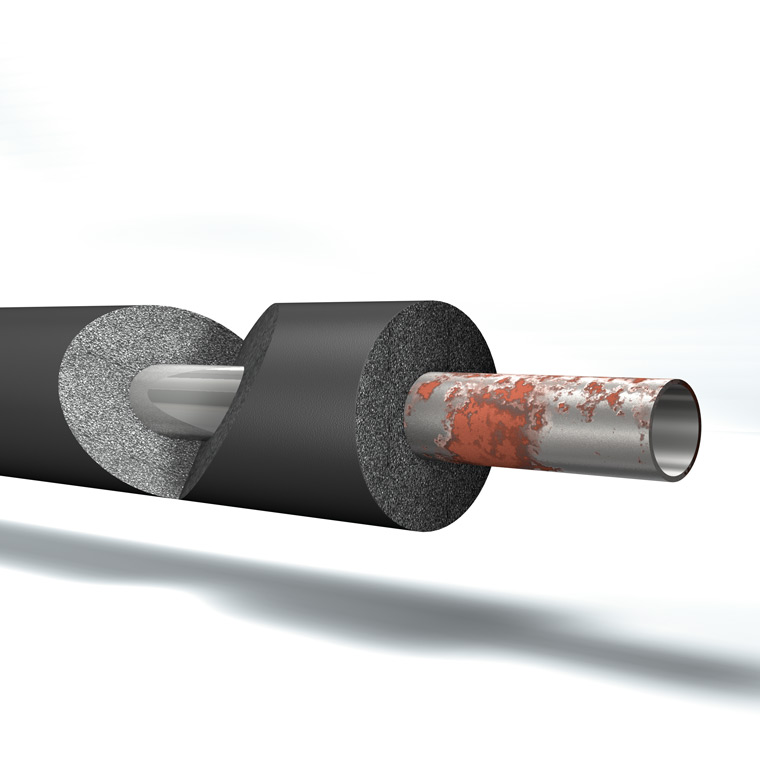

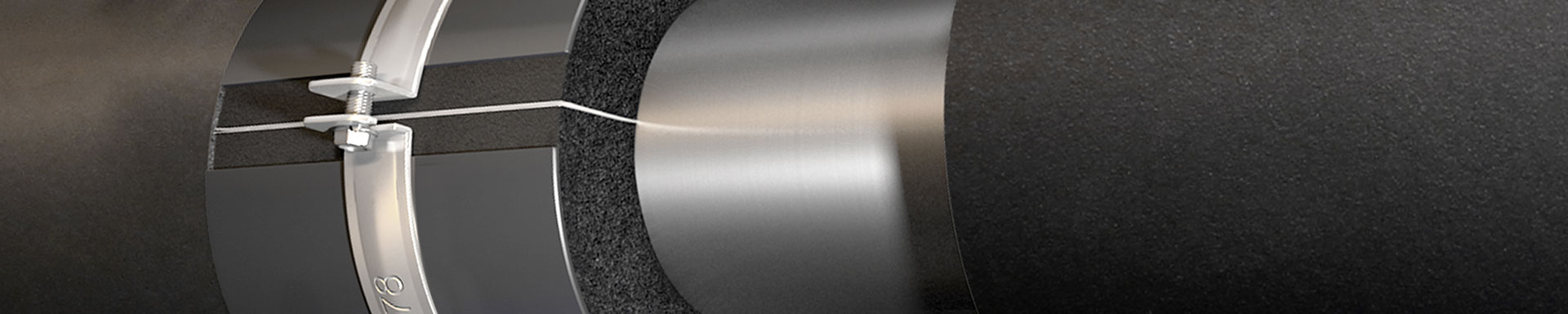

Minimise corrosion under insulation (CUI)

Corrosion under insulation is a significant concern in industrial applications, causing pipe and metal cladding systems to rust and decay, which can lead to unexpected shutdowns and costly maintenance work. Closed-cell insulation, like ArmaFlex®, and hydrophobic ArmaGel® solutions, have a proven track record in reducing the onset and spread of CUI, confirmed with specially designed long-term tests. Compared to conventional materials, they display the highest protective qualities, offering an effective barrier against moisture ingress to safeguard equipment and pipework infrastructure. ArmaFlex insulation can be finally protected with specially designed non-metallic ArmaCladTM products including Arma-Chek R, Arma-Chek D, Arma-Chek Silver, and pre-covered solutions, depending on the type of project.

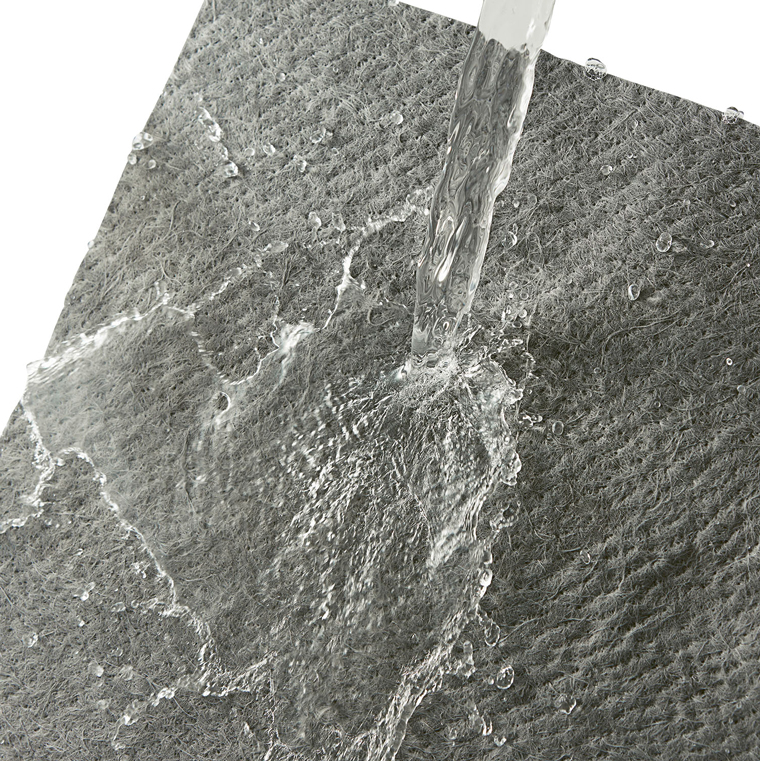

Maximise energy efficiency and process stability

Reducing heat loss or gain of process lines and equipment is key to achieving energy-efficient processes. Our ArmaFlex® and ArmaGel® solutions are designed to enhance performance continuity, boasting low thermal conductivity and fitting more snugly to complex geometries. This unique design enables professionals to minimise heat loss or gain more effectively than with conventional insulation materials, leading to improved operational efficiency, process stability and cost savings.

Reduce noise

Acoustic control of pipework and equipment is a crucial parameter in processing industries to ensure safe and comfortable working conditions and to satisfy environmental targets. Armacell's ArmaSound® Industrial Systems are regularly tested by accredited institutes and comply, and often exceed, the requirements of leading noise control standards. Whether ISO 15665, Shell DEP 31.46.00.31, NORSOK, or ASTM E1222, our solutions provide effective noise control for all applications.

Rely on Passive Fire Protection (PFP)

Safety is paramount in industrial settings, particularly in high-temperature applications. Specialised materials, such as elastomers are characterised by high elasticity in a broad temperature range, able to withstand fully developed fires throughout a significant timespan – such as ArmaFlex® Protect for penetration seals. Plus, our new generation of ArmaGel® HTF aerogel fire protection blankets are designed to withstand temperatures of +650 ºC (+1200 ºF). Officially tested for up to 120 minutes, our UL 1709-compliant solution provides reliable passive fire protection, reducing the risk of shut-downs at the same time as protecting your assets.

Save time and installation cost

Technical insulation should be high-performing and also quick and easy to install. Our highly flexible materials enable professionals to save installation time, improve space efficiency and minimise rework and wastage, resulting in a smaller environmental footprint and lower overall project costs due to a reduction in supporting steelwork, cladding materials, and installation expenses. With just a few materials, installers can accommodate complex shapes easily and directly at the jobsite or even pre-fabricate it at the workshop. Maintenance and partial replacement is also easy with our flexible elastomeric products.

Your holistic partner and advisor

Your holistic partner and advisor

We understand that every processing pipework system is unique. As an experienced partner in technical insulation, we are committed to finding the right insulation solution for your project – from insulation materials and their configuration to adhesives and accessories as well as cladding and pre-covered products. By sharing our system expertise and technical know-how, we provide you with a complete solution for your equipment to achieve your desired thermal and acoustic performance and energy-saving targets.

Rely on high quality and durability

Rely on high quality and durability

The insulation you choose must be durable to withstand wear and tear and achieve maximised lifetime performance. As a global leader in insulation materials, we deliver the highest quality and longevity, conducting more than 30,000 quality tests each year and constantly optimizing our materials to offer best-in-class solutions for your projects.

Lower your total cost of ownership

Lower your total cost of ownership

Insulation is essential to the operational reliability of mechanical equipment. To avoid high maintenance, repair, and consequential costs, the technical performance and reliability of the installation must always be the deciding factor when selecting equipment insulation. Our comprehensive range of high-performing system solutions and products ensures long-term reliable results. Armacell materials allow for spot repairs, ensuring that if properly installed sections are damaged, they can be restored to their original efficiency. This extends the life of the insulation and reduces the need for costly full-scale replacements, significantly lowering maintenance and repair expenses over the lifetime of the insulation.

Get installation support

Get installation support

We believe that insulation material is only as valuable as the quality of its installation. That’s why we are continuously building a growing network of certified installers, ready to use our high-quality materials effectively and professionally. Our dedicated Armacell trainers offer structured on-site and off-site training courses and certifications. This is complemented by self-service tools, including application manuals and videos to support installers and contractors during specification and installation.

Benefit from our Energy Assessment

Our Energy Assessments – performed onsite by our technical experts - are an effective way to assess your energy losses across your facility and to determine the right course of action for BEYOND BETTER energy efficiency, productivity and process stability.

Discover our Installation Training

Our commitment to providing high-performing insulation technology goes beyond high-quality materials. It involves sharing our expertise on the right installation of our insulation systems. In our training programmes, we equip you with the necessary expertise to install our solutions reliably, safely and quickly.

Discover our Acoustic Consultancy Service

From initial design to project completion, our comprehensive acoustic consultancy service provides acoustic measurements, modelling, and advice, ensuring effective noise control solutions for your project's success. This deep understanding forms the foundation for our wide range of tailored solutions.